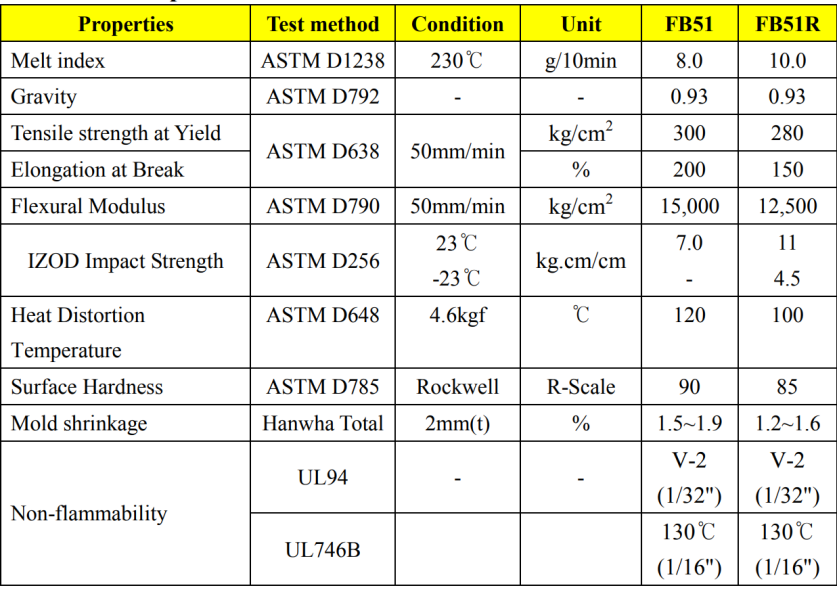

Non-flammable PP FB51 and FB5lR, which are designed with base resin that has excellent shock resistance, exhibit high shock resistance. In particular, its excellent fluidity allows good formability and nice exterior with high non-flammability so to be widely used for exterior of electric/electronic parts.

(1) FB51

As non-flammability grade of UL94 V-2, it provides fluidity and shock resistance, nice exterior, in particular, long-term thermal stability. Thus, it belongs to UL746B RTI 130℃ Class, the world top standard, as PP material. It is widely used for exterior of heat transmission/electric/electronic products like a fan heater.

(1) FB51R

As non-flammability grade of UL94 V-2, it provides long-term thermal stability as well as excellent shock resistance in lowtemperature(-20℃). Thus, it keeps high shock resistance regardless of use circumstance, even in winter. It is widely used for exterior of heat transmission/electric/electronic products like a fan heater.

2.1 Applications

· Fan heater exterior (FB51,FB51R)

· Other electric/electronic parts needing shock resistance and non-flammability(FB51, FB51R)

2.2 Major Property Requirements

· Non-flammability (UL94 V-2)

· Long-term heat-resist stability (UL746B)

· High heat-resistance

· Dimensional Stability

· Property balance between rigidity and shock resistance

2.3 General Processing Guide

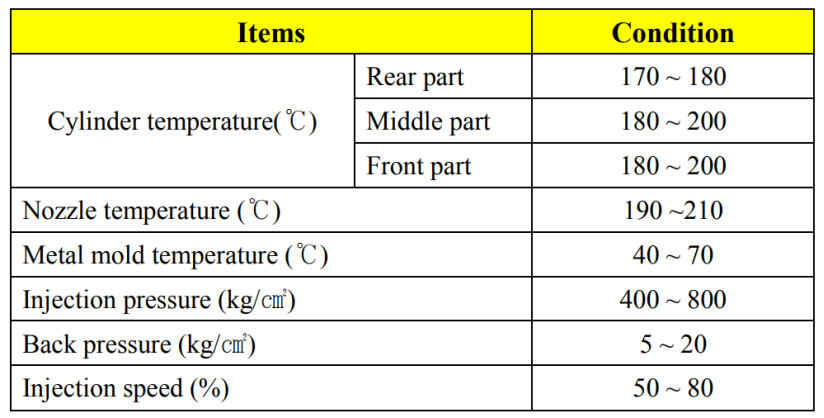

· High shock-resist and non-flammable PP, FB5l and FB5lR, have a similar processing condition as the previous non-flammable PP. While separatedrying before molding is not necessary, drying for about 2 hours at90~100℃ helps to get better appearance of a molding product in processing.

· Use in high temperature causes dismantlement so that it is molded under 220℃ of the resin temperature.

· There would be no problem when molding in normal cycle time. In order to avoid dismantlement of non-flammable agents among residual resin, the residual resin in the cylinder should be purged and cleaned with flammable PP at both break and finish.

Standard PP processing conditions may be applied, and the typical processingconditions are as follows:

2.4 Physical Properties

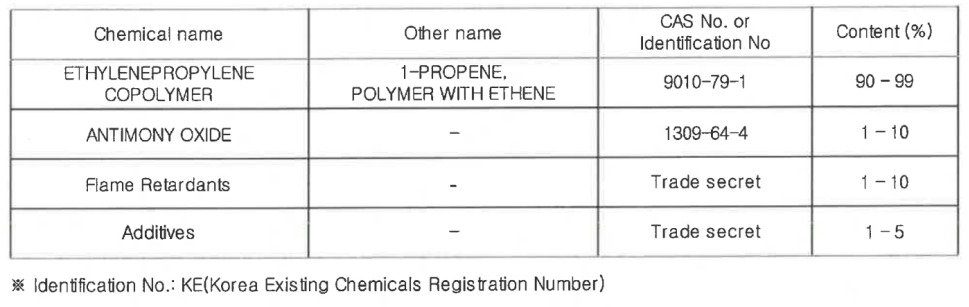

Resin Properties

2.5 Food Contact Application

· Hanwha Total FB51, FB5lR are not intended for use in food-contact andmedical applications either.