1. 什么是 PP PPH-MM90?

PP PPH-MM90 是恒力石化生产的一种高性能聚丙烯(PP)材料。它具有高透明度、高流动性和良好的耐热性,适用于注塑成型工艺。广泛应用于食品包装、家电(透明面板)、医疗用品(一次性注射器、药品包装)、日用品(透明收纳盒、化妆品包装)等领域。

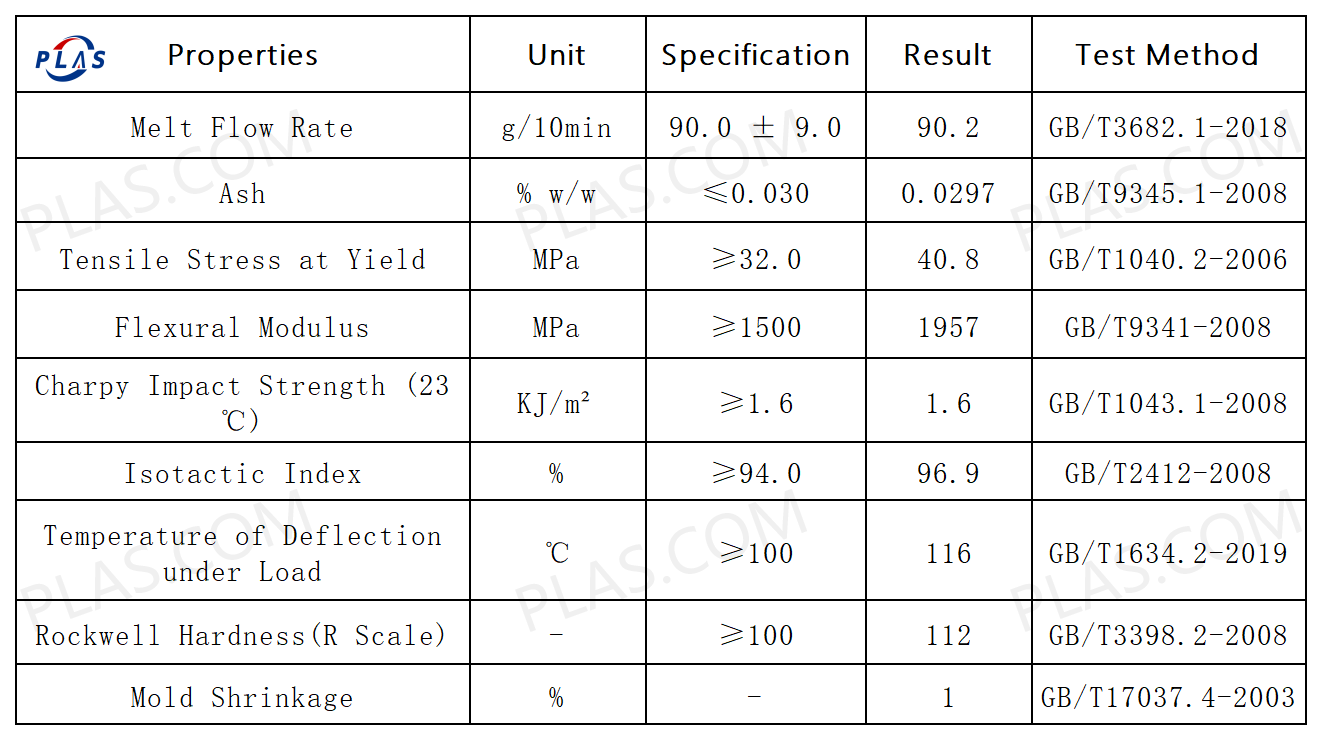

2. 材料物性

合成工艺

其生产过程包括聚合丙烯单体(C3H6),并通过催化剂和特定工艺将气态丙烯转化为固态聚合物。让我们逐步了解其化学合成过程:

2.1 原料制备

丙烯(C3H6):来自石油或天然气裂解。需要高纯度的丙烯作为单体。

催化剂: 常用齐格勒-纳塔催化剂或茂金属催化剂。PP PPH-MM90 大多使用 Ziegler-Natta 催化体系,以提高结晶度和机械性能。

助催化剂:如三乙基铝(TEA)或甲基铝氧烷(MAO),用于提高催化剂的活性。

2.2 聚合(丙烯聚合)

在聚合反应器中,丙烯气体被加压,并在催化剂的作用下聚合。温度通常保持在 60-80℃,压力为 2-3MPa。

丙烯通过催化剂上的活性位点发生加成反应,形成长链聚丙烯分子。

化学反应方程式:

2.3 聚合物分离和后处理

聚合后的固体聚丙烯颗粒从反应器中分离出来,并除去催化剂和未反应的单体。

为了改善材料的性能,可以混合添加剂,如抗氧化剂、紫外线稳定剂、加工助剂等。

2.4 造粒和包装

熔融聚丙烯经挤出机造粒,形成均匀的 PP PPH-MM90 树脂颗粒。

最后,对其进行冷却、干燥和包装,准备供应给注塑成型和塑料加工公司。

这种生产工艺确保 PP PPH-MM90 具有优异的熔体流动性、刚性、耐热性和尺寸稳定性,非常适合薄壁注塑成型应用。

3. 应用领域

食品包装:透明食品容器、饮料杯、保鲜盒等。

家用电器:透明面板、控制旋钮和其他部件。

医疗用品:一次性注射器、药品包装等。

日用品:透明收纳盒、化妆品包装等。

4. 市场情况

从全球聚丙烯市场来看,预计 2022 年市场规模将达到 1234.6 亿美元,2023 年至 2030 年的年复合增长率将达到 4.7%。这表明聚丙烯产品的需求正在稳步增长。

PP PPH-MM90 作为恒力石化的主要聚丙烯产品,市场价格稳定,应用前景广阔。作为全球领先的炼化一体化企业,恒力石化业务涵盖炼油、石化、聚酯新材料和纺织等领域。其生产的聚丙烯产品质量稳定,广泛应用于各种塑料制品的生产,市场占有率稳定。