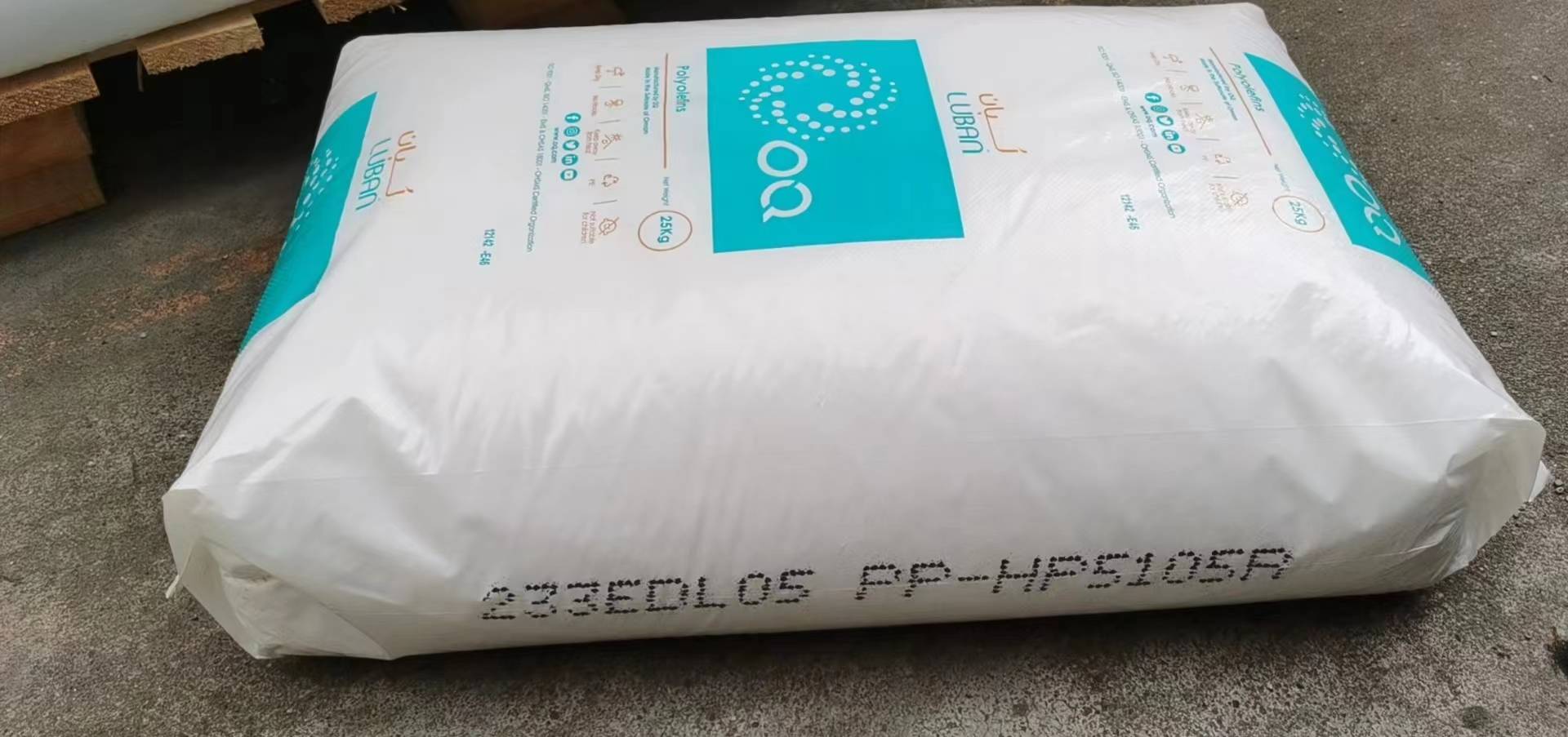

PP HP5105R OPP OMAN

249

- Unit Price:US$ 1,465 /MT

- Packaging Specification:25 KG/PKG

- Packaging Material:Paper bag

- Supply Quantity:49.8MT

- Delivery Terms:FOB

- Port of Loading :China Main Port

- Accepted Payment Methods:T/T

- Shipping:Negotiate supplier for shipping details

Supplier Information

ASIA PLASTIC EXCHANGE LIMITED

+86 755 ********View

serv********View

+86 ********View

For more details, please contact the supplier!

Material Description

- Material Properties:--

- Application Areas:--

- Color:--

- Grade:Injection grade

Technical Data Sheet

| impact performance | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Impact strength of simply supported beam without notch | 23°C | ISO 179/1eU | 110 kJ/m² |

| 23°C | 简支梁Unnotched冲击强度 | ISO 179/1eU | 110 kJ/m² |

| 简支梁Notched冲击强度 | ISO 179/1eA | 2.5 kJ/m² |

| squeeze out | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Temperature in Zone 4 of the material cylinder | 210 to 240 °C | ||

| Temperature in Zone 3 of the material cylinder | 210 to 240 °C | ||

| Temperature in Zone 2 of the material cylinder | 210 to 240 °C | ||

| Temperature in Zone 1 of the material cylinder | 210 to 240 °C |

| mechanical properties | Test Condition | Test Method | Test Result |

|---|---|---|---|

| crack | 拉伸Strain | > 50 % | |

| yield | 拉伸Strain | 8 % | |

| 拉伸应力 | ISO 527-2/50 | 35 Mpa | |

| Tensile strain | Break | > 50 % | |

| Yield | 8 % | ||

| tensile strength | Yield | ISO 527-2/50 | 35 Mpa |

| Tensile modulus | ISO 527-1/1 | 1500 Mpa |

| thermal performance | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Hot deformation temperature | 0.45 MPa, Unannealed | ISO 75-2/B | 85 °C |

| Physical properties | Test Condition | Test Method | Test Result |

|---|---|---|---|

| 230°C/2.16 kg | 熔流率(熔体Flow速率) | ISO 1133 | 24 g/10 min |

| melt mass-flow rate | 230°C/2.16 kg | ISO 1133 | 24 g/10 min |

IMPORTANT NOTES: Plas.com collected the data in the data sheet from the material manufacturers. Plas.com makes the best effort to improve the accuracy of the data, but has no responsibility for the data. We strongly recommend verifying the validity of the data with the material manufacturers before making a final decision.