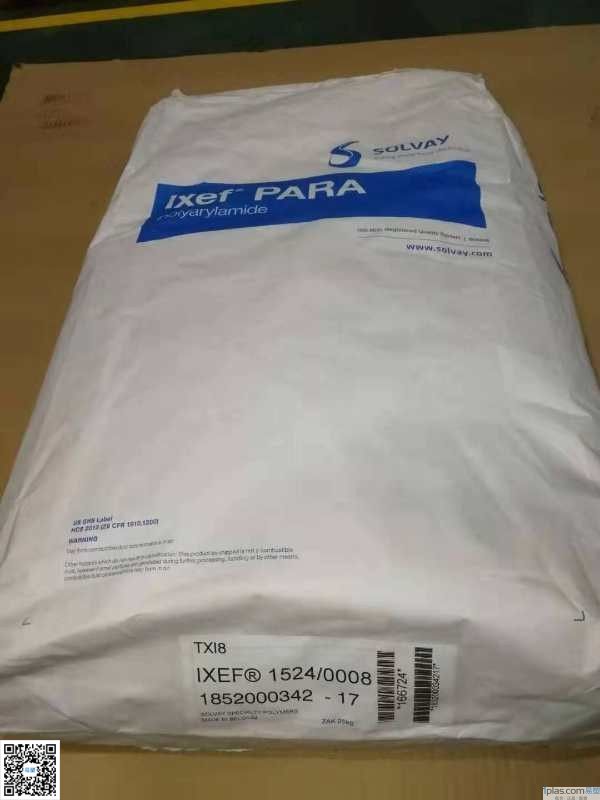

PARA IXEF® 1524 0008

69

- Properties:high strengthCreep resistanceFiller: Glass fiber reinf50% filler by weight

- Usages:sporting goodsShellPhone

Technical Data Sheet

| physical property | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Shrinkage rate | 内部方法 | 0.10-0.30 % | |

| Water absorption rate | ISO 62 | 0.30 % | |

| 内部方法 | 1.0 % | ||

| 内部方法 | 1.3 % |

| flammability | Test Condition | Test Method | Test Result |

|---|---|---|---|

| UL flame retardant rating | UL 94 | V-0 | |

| Hot filament ignition temperature | IEC 60695-2-13 | 775 °C | |

| IEC 60695-2-13 | 800 °C | ||

| IEC 60695-2-13 | 825 °C | ||

| IEC 60695-2-13 | 850 °C | ||

| Limiting Oxygen Index | ISO 4589-2 | 37 % |

| Mechanical properties | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Tensile modulus | ISO 527-2 | 20000 Mpa | |

| tensile strength | ISO 527-2 | 230 Mpa | |

| Tensile strain | ISO 527-2 | 1.9 % | |

| Flexural modulus | ISO 178 | 18500 Mpa | |

| bending strength | ISO 178 | 330 Mpa |

| Impact resistance | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Impact strength of simply supported beam without notch | ISO 179/1eU | 48 kJ/m² |

| Electrical performance | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Compared to the Leakage Tracking Index (CTI) | UL 746 | PLC 0 | |

| UL 746 | PLC 0 | ||

| IEC 60112 | PLC 0 | ||

| High arc combustion index (HAI) | UL 746 | PLC 2 | |

| UL 746 | PLC 2 | ||

| UL 746 | PLC 1 | ||

| UL 746 | PLC 1 | ||

| UL 746 | PLC 2 | ||

| UL 746 | PLC 2 | ||

| UL 746 | PLC 1 | ||

| UL 746 | PLC 1 | ||

| High Voltage Arc Traceability Rate (HVTR) | UL 746 | PLC 0 | |

| Hot wire ignition (HWI) | UL 746 | PLC 1 sec | |

| UL 746 | PLC 0 sec | ||

| UL 746 | PLC 0 sec | ||

| UL 746 | PLC 0 sec | ||

| UL 746 | PLC 1 | ||

| UL 746 | PLC 0 | ||

| UL 746 | PLC 0 | ||

| UL 746 | PLC 0 | ||

| dielectric constant | ASTM D2520 | 4.44 | |

| Dissipation Factor | ASTM D2520 | 0.012 |

| Thermal performance | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Heat distortion temperature | ISO 75-2/A | 227 °C |

IMPORTANT NOTES: Plas.com collected the data in the data sheet from the material manufacturers. Plas.com makes the best effort to improve the accuracy of the data, but has no responsibility for the data. We strongly recommend verifying the validity of the data with the material manufacturers before making a final decision.

You May Like

Contact Us

Get App

Top