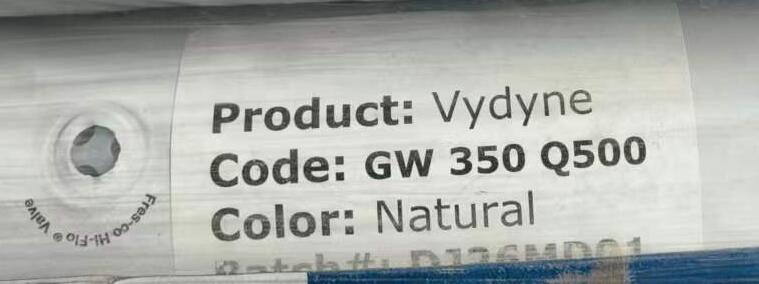

PA66 GW 350 Q500 NA

25

- Usages:Electrical appliancesElectrical enclosureswitchFastenersElectrical/Electronic ApplicationsSpoolVehicle electronicsLighting applicationsprinted circuit boardLaptop caseMovable hingeIndustrial applicationsElectrical components

Technical Data Sheet

| physical property | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Shrinkage rate | ISO294-4 | 1.8 % | |

| ISO294-4 | 1.3 % | ||

| Water absorption rate | ISO62 | 2.1 % |

| flammability | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Burning wire flammability index | IEC60695-2-12 | 960 °C | |

| IEC60695-2-12 | 960 °C | ||

| IEC60695-2-12 | 960 °C | ||

| Hot filament ignition temperature | IEC60695-2-13 | 930 °C | |

| IEC60695-2-13 | 900 °C | ||

| IEC60695-2-13 | 850 °C | ||

| IEC60695-2-13 | 825 °C | ||

| UL flame retardant rating | UL94 | V-2 | |

| UL94 | V-2 | ||

| UL94 | V-2 | ||

| UL94 | V-2 | ||

| Burning wire flammability index | IEC60695-2-12 | 960 °C |

| Mechanical properties | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Tensile stress | ISO527-2 | 83.0 Mpa | |

| Tensile strain | ISO527-2 | 17 % | |

| Flexural modulus | ISO178 | 3340 Mpa | |

| Poisson's ratio | ISO527-2 | 0.40 |

| Electrical performance | Test Condition | Test Method | Test Result |

|---|---|---|---|

| dielectric strength | IEC60243 | 14 KV/mm | |

| arc resistance | ASTMD495 | PLC 5 | |

| CTI | IEC60112 | 250to399 V | |

| High arc combustion index (HAI) | UL746 | PLC 0 | |

| UL746 | PLC 0 | ||

| UL746 | PLC 0 | ||

| UL746 | PLC 0 | ||

| High Voltage Arc Traceability Rate (HVTR) | UL746 | PLC 4 | |

| Hot wire ignition (HWI) | UL746 | PLC 4 | |

| UL746 | PLC 4 | ||

| UL746 | PLC 0 | ||

| UL746 | PLC 0 |

| Thermal performance | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Heat distortion temperature | ISO75-2/A | 65.0 °C | |

| melting temperature | ISO11357-3 | 263 °C |

IMPORTANT NOTES: Plas.com collected the data in the data sheet from the material manufacturers. Plas.com makes the best effort to improve the accuracy of the data, but has no responsibility for the data. We strongly recommend verifying the validity of the data with the material manufacturers before making a final decision.

You May Like

Contact Us

Get App

Top