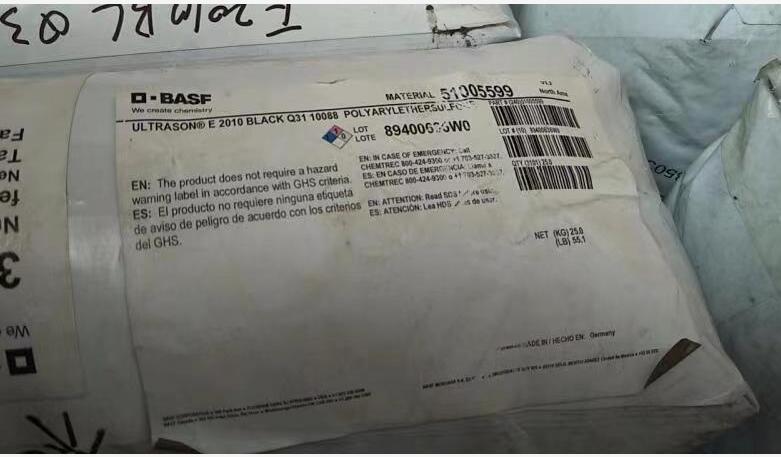

PES Ultraform®E E2010 BLACK Q31 10088 BASF GERMANY

35

- Properties:Dimensional stabilityHigh mobilityNon enhancedHigh temperature resistan

- Usages:Vehicle electronicsLaptop caseHome FurnishingsAutomotive Applications

Technical Data Sheet

| impact performance | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Impact strength of cantilever beam gap | 23°C | ISO 180 | 7.0 kJ/m² |

| -30°C | ISO 180 | 7.5 kJ/m² | |

| Impact strength of simply supported beam without notch | 23°C | ISO 179 | NoBreak |

| -30°C | ISO 179 | NoBreak | |

| Charpy Notched Impact Strength | -30°C | ISO 179 | 7.5 kJ/m² |

| 23°C | ISO 179 | 7.0 kJ/m² |

| flammability | Test Condition | Test Method | Test Result |

|---|---|---|---|

| UL flame retardant rating | 3.0mm | UL 94 | V-0 |

| 1.6mm | UL 94 | V-0 |

| mechanical properties | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Tensile modulus | 23°C | ISO 527-2 | 2650 Mpa |

| tensile strength | Yield,23°C | ISO 527-2 | 85.0 Mpa |

| Tensile strain | Yield,23°C | ISO 527-2 | 6.9 % |

| thermal performance | Test Condition | Test Method | Test Result |

|---|---|---|---|

| RTI Str | 3.0mm | UL 746 | 190 °C |

| 1.6mm | UL 746 | 190 °C | |

| RTI Imp | 3.0mm | UL 746 | 180 °C |

| 1.6mm | UL 746 | 180 °C | |

| RTI Elec | 3.0mm | UL 746 | 180 °C |

| 1.6mm | UL 746 | 180 °C | |

| Linear coefficient of thermal expansion | MD | 5.2E-05 cm/cm/°C | |

| Hot deformation temperature | 1.8MPa,Unannealed | ISO 75-2/A | 205 °C |

| Physical properties | Test Condition | Test Method | Test Result |

|---|---|---|---|

| density | ISO 1183 | 1.37 g/cm³ | |

| Melt Volume Flow Rate (MVR) | 360°C/10.0kg | ISO 1133 | 70.0 cm3/10min |

| Shrinkage rate | TD | ISO 294-4 | 0.86 % |

| MD | ISO 294-4 | 0.82 % | |

| Water absorption rate | Saturation,23°C | ISO 62 | 2.2 % |

| Equilibrium,23°C,50%RH | ISO 62 | 0.80 % |

| Electrical performance | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Dissipation factor | 1MHz | IEC 60250 | 0.014 |

| 100Hz | IEC 60250 | 1.7E-03 | |

| Volume resistivity | IEC 60093 | >1.0E+13 ohms·cm | |

| Surface resistivity | IEC 60093 | >1.0E+15 ohms | |

| Compared to the anti leakage trace index | IEC 60112 | PLC 4 | |

| Dielectric constant | 1MHz | IEC 60250 | 3.80 |

| 100Hz | IEC 60250 | 3.90 | |

| Dielectric strength | IEC 60243-1 | 37 KV/mm |

| hardness | Test Condition | Test Method | Test Result |

|---|---|---|---|

| Ball Pressure Test | ISO 2039-1 | 154 Mpa |

IMPORTANT NOTES: Plas.com collected the data in the data sheet from the material manufacturers. Plas.com makes the best effort to improve the accuracy of the data, but has no responsibility for the data. We strongly recommend verifying the validity of the data with the material manufacturers before making a final decision.