Material Comparison

Product Info

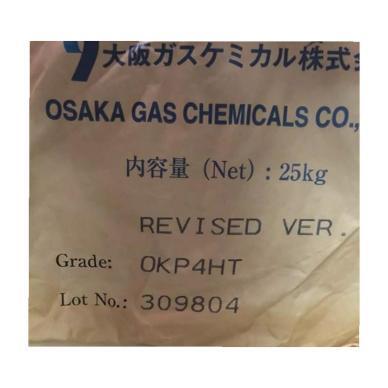

Product Name

Brand Name

Usages

Properties

Certificates

COC OKP4HT OSAKA GAS JAPAN

Polyester

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

| machinability | Test Condition | Test Method | OSAKA GAS JAPAN/OKP4HT |

|---|---|---|---|

| Dry conditions | 80°-90°五小时以上 | ||

| Melt Temperature | 280 ℃(℉) | ||

| Mold temperature | 100-120 ℃(℉) | ||

| Processing temperature | 300 ℃(℉) | ||

| Screw speed | 20mm/s rpm |

| thermal performance | Test Condition | Test Method | OSAKA GAS JAPAN/OKP4HT |

|---|---|---|---|

| Combustibility (rate) | UL 94 | HB | |

| Glass transition temperature | ASTM D785 | 142 ℃(℉) | |

| Hot deformation temperature | HDT | ASTM D648/ISO 75 | 128 ℃(℉) |

| mechanical properties | Test Condition | Test Method | OSAKA GAS JAPAN/OKP4HT |

|---|---|---|---|

| Bending modulus | ASTM D790/ISO 178 | 65 kg/cm²(MPa)[Lb/in²] | |

| bending strength | ASTM D790/ISO 178 | 115 kg/cm²(MPa)[Lb/in²] | |

| Charpy Notched Impact Strength | ASTM D256/ISO 179 | 43 kg·cm/cm(J/M)ft·lb/in | |

| elongation | ASTM D638/ISO 527 | 2500 % | |

| Elongation at Break | ASTM D638/ISO 527 | 2500 kg/cm²(MPa)[Lb/in²] | |

| Impact strength of cantilever beam gap | ASTM D256/ISO 179 | 45 kg·cm/cm(J/M)ft·lb/in | |

| Tensile modulus | ASTM D638/ISO 527 | 10 kg/cm²(MPa)[Lb/in²] | |

| tensile strength | ASTM D638/ISO 527 | 65 kg/cm²(MPa)[Lb/in²] |

| other | Test Condition | Test Method | OSAKA GAS JAPAN/OKP4HT |

|---|---|---|---|

| characteristic | 耐热.折射率优良 | ||

| Color | 透明 | ||

| purpose | 800万像素镜头.光学镜片 | ||

| remarks | 800万像素镜头 |

| Physical properties | Test Condition | Test Method | OSAKA GAS JAPAN/OKP4HT |

|---|---|---|---|

| density | ASTM D792/ISO 1183 | 1.26 | |

| melt mass-flow rate | ASTM D1238/ISO 1133 | 10 g/10min | |

| Shrinkage rate | ASTM D955 | 0.7 % | |

| Water absorption rate | ASTM D570/ISO 62 | 0.2 % |

| optical performance | Test Condition | Test Method | OSAKA GAS JAPAN/OKP4HT |

|---|---|---|---|

| Fuzzy coefficient (Haze) | ISO 14782 | 83% % | |

| gloss | 90% | ||

| Refractive index | ASTM D542/ISO 489 | 1.632 | |

| Transmittance rate | ASTM D1003/ISO 13468 | 90 % |