Material Comparison

Product Info

Product Name

Brand Name

Usages

Properties

Certificates

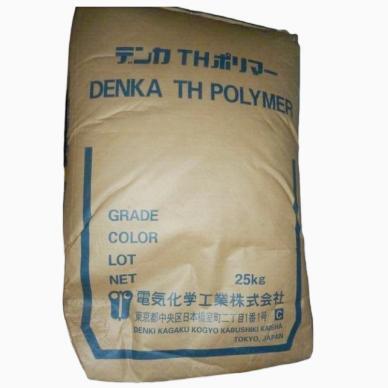

ABS CU-301 DENKA JAPAN

--

--

High impact resistance、transparent

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

| Basic performance | Test Condition | Test Method | DENKA JAPAN/CU-301 |

|---|---|---|---|

| melt mass-flow rate | 200℃*5kg | JIS K-6874 | 1.4 g/10min |

| 220℃*10kg | JIS K-6874 | 18 g/10min |

| Mechanical properties | Test Condition | Test Method | DENKA JAPAN/CU-301 |

|---|---|---|---|

| bending strength | ASTM D790/ISO 178 | 61 kg/cm²(MPa)[Lb/in²] | |

| Impact strength of cantilever beam gap | ASTM D256/ISO 179 | 180 kg·cm/cm(J/M)ft·lb/in | |

| Rockwell hardness | M尺度 | ASTM D-785 | 33 |

| Flexural modulus | ASTM D790/ISO 178 | 1770 kg/cm²(MPa)[Lb/in²] | |

| Rockwell hardness | R尺度 | ASTM D-785 | - |

| Flexural modulus | ASTM D-790 | 1770 Mpa | |

| bending strength | ASTM D-790 | 61 Mpa | |

| Impact strength of cantilever beam gap | 1/4"带缺口 | ASTM D-256 | 180 J/m |

| tensile strength | ASTM D-638 | 33 Mpa | |

| Rockwell hardness | ASTM D785 | 33 | |

| tensile strength | ASTM D638/ISO 527 | 33 kg/cm²(MPa)[Lb/in²] |

| Physical properties | Test Condition | Test Method | DENKA JAPAN/CU-301 |

|---|---|---|---|

| Shrinkage rate | ASTM D955 | 3-5 % | |

| density | ASTM D792/ISO 1183 | 1.10 | |

| melt mass-flow rate | ASTM D1238/ISO 1133 | 1.4 g/10min |

| processability | Test Condition | Test Method | DENKA JAPAN/CU-301 |

|---|---|---|---|

| Shrinkage rate | 2mmt | 0.3-0.5 % |

| physical property | Test Condition | Test Method | DENKA JAPAN/CU-301 |

|---|---|---|---|

| Total Light Transmittance | 2mmt | ASTM D-1003 | 90.5 % |

| Haze ratio | 2mmt | ASTM D-1003 | 1.5 % |

| Thermal performance | Test Condition | Test Method | DENKA JAPAN/CU-301 |

|---|---|---|---|

| vicat | 5kg | JIS K-7206 | 80 °C |

| Heat distortion temperature | HDT | ASTM D648/ISO 75 | 71 ℃(℉) |

| vicat | ASTM D1525/ISO R306 | 80 ℃(℉) | |

| Heat distortion temperature | 12.7mm,1.82MPa,HDT | ASTM D-648 | - °C |

| 6.4mm,1.82MPa,HDT | ASTM D-648 | 71 °C | |

| combustibility | 垂直燃烧性 | UL -94 | 1.5mmHB |

Contact Us

Get App

Top