Material Comparison

Product Info

Product Name

Brand Name

Usages

Properties

Certificates

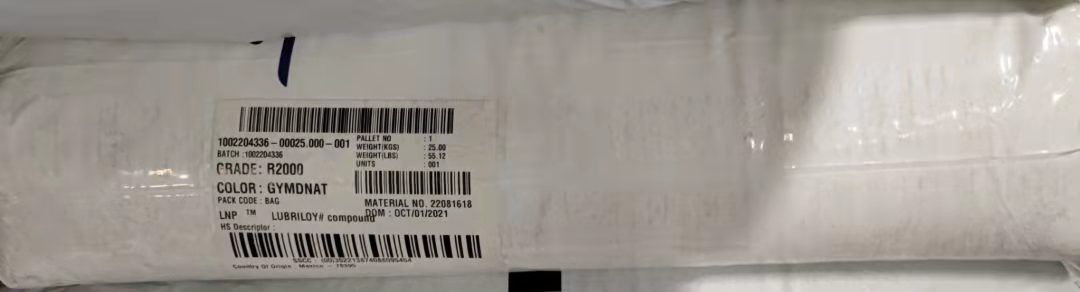

PA66 R2000 GYMDNAT SABIC INNOVATIVE MEXICO

LNP™ LUBRILOY™ Compound

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

| Impact resistance | Test Condition | Test Method | SABIC INNOVATIVE MEXICO/R2000 GYMDNAT |

|---|---|---|---|

| Suspended wall beam without notch impact strength | 23°C | ASTM D4812 | 1700 J/m |

| 23°C4 | ISO 180/1U | 140 kJ/m² |

| Mechanical properties | Test Condition | Test Method | SABIC INNOVATIVE MEXICO/R2000 GYMDNAT |

|---|---|---|---|

| elongation | 屈服 | ASTM D638 | 14 % |

| tensile strength | 断裂 | ASTM D638 | 55.0 Mpa |

| 断裂 | ISO 527-2 | 53.0 Mpa | |

| Flexural modulus | -- | ISO 178 | 2000 Mpa |

| bending strength | -- | ISO 178 | 65.0 Mpa |

| coefficient of friction | Dynamic | ASTM D3702 | 0.36 |

| Tensile modulus | ASTM D638 | 2410 Mpa | |

| elongation | 断裂 | ASTM D638 | 27 % |

| bending strength | -- | ASTM D790 | 82.0 Mpa |

| tensile strength | 屈服 | ASTM D638 | 56.0 Mpa |

| coefficient of friction | Static | ASTM D3702 | 0.27 |

| Flexural modulus | -- | ASTM D790 | 2310 Mpa |

| elongation | 断裂 | ISO 527-2 | 32 % |

| Wear factor | ASTM D3702 | 1.0E+7 10^-8 mm³/N·m |

| physical property | Test Condition | Test Method | SABIC INNOVATIVE MEXICO/R2000 GYMDNAT |

|---|---|---|---|

| Shrinkage rate | 流动 : 24小时 | ASTM D955 | 1.8 - 2.2 % |

| Water absorption rate | 24 hr, 50% RH | ASTM D570 | 0.25 % |

| Shrinkage rate | 横向流动 : 24小时 | ASTM D955 | 2.1 - 3.1 % |

| Thermal performance | Test Condition | Test Method | SABIC INNOVATIVE MEXICO/R2000 GYMDNAT |

|---|---|---|---|

| Linear coefficient of thermal expansion | 流动 : -40 到 40°C | ASTM E831 | 7.7E-5 cm/cm/°C |

| Heat distortion temperature | 1.8 MPa, 未退火, 4.00 mm, 64.0 mm 跨距4,HDT | ISO 75-2/Af | 85.0 °C |

| Linear coefficient of thermal expansion | 横向 : -40 到 40°C | ASTM E831 | 1.0E-4 cm/cm/°C |

| Heat distortion temperature | 1.8 MPa, 未退火, 3.20 mm,HDT | ASTM D648 | 77.0 °C |

| injection | Test Condition | Test Method | SABIC INNOVATIVE MEXICO/R2000 GYMDNAT |

|---|---|---|---|

| drying time | 4.0 hr | ||

| screw speed | 30 to 60 rpm | ||

| Suggested maximum moisture content | 0.15 to 0.25 % | ||

| Temperature in the middle of the barrel | 280 to 295 °C | ||

| Temperature at the rear of the barrel | 265 to 275 °C | ||

| Processing (melt) temperature | 270 to 280 °C | ||

| drying temperature | 80 °C | ||

| Temperature at the front of the material cylinder | 295 to 305 °C | ||

| Back pressure | 0.200 to 0.300 Mpa | ||

| Temperature | 80 to 95 °C |

Contact Us

Get App

Top