Material Comparison

Product Info

Product Name

Brand Name

Usages

Properties

Certificates

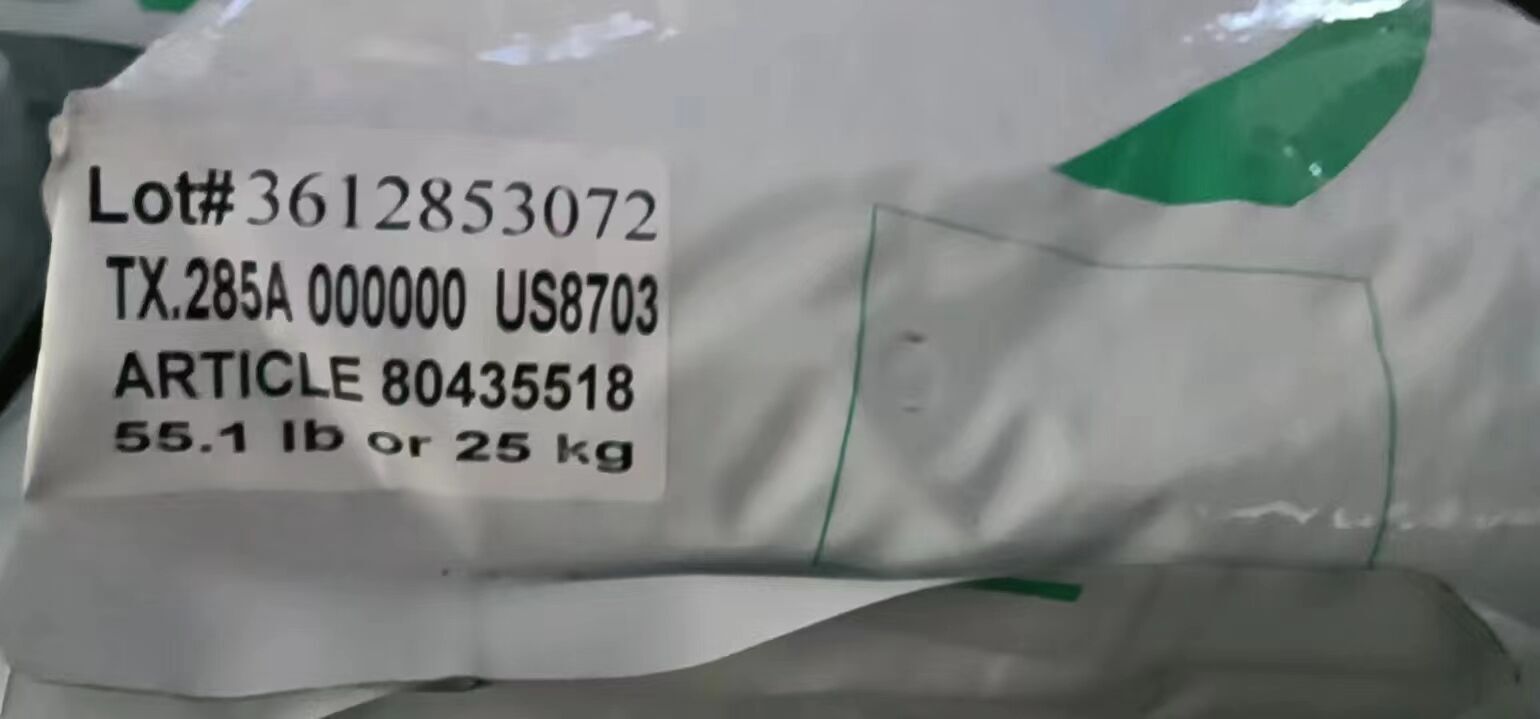

TPU 285A COVESTRO USA

Texin®

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

physical property

Test Condition

Test Method

Unit

TPU/COVESTRO USA/285A

density

ASTM D792

g/cm³

1

density

ISO 1183

g/cm³

1

Shrinkage rate

流动2.5mm

ASTM D955

%

0

Shrinkage rate

垂直2.5mm

ASTM D955

%

0

Shrinkage rate

垂直2.5mm

ISO 2577

%

0

Shrinkage rate

流动2.5mm

ISO 2577

%

0

Mechanical performance

Test Condition

Test Method

Unit

TPU/COVESTRO USA/285A

Bayshore Elasticity

ASTM D2632

%

4

tensile strength

50%应变

ISO 37

Mpa

5

tensile strength

100%应变

ASTM D412

Mpa

5

tensile strength

300%应变

ASTM D412

Mpa

1

tensile strength

屈服

ASTM D412

Mpa

3

tensile strength

屈服

ISO 37

Mpa

3

elongation

断裂

ASTM D412

%

5

elongation

断裂

ISO 37

%

5

Tear Man apart

C型

ASTM D624

kN/m

8

tear strength

ISO 34

kN/m

8

Tiber wear and tear

H-18轮1kg 1000次循环

ASTM D1044

mg

3

Tiber wear and tear

H-18轮1kg 1000次循环

ISO 4649

mg

3

Bending modulus

-30℃

ISO 178

Mpa

4

Bending modulus

23℃

ASTM D790

Mpa

2

compressive strength

10%应变

ASTM D575

Mpa

2

compressive strength

15%应变

ASTM D575

Mpa

3

compressive strength

2%应变

ASTM D575

Mpa

0

compressive strength

20%应变

ASTM D575

Mpa

4

compressive strength

25%应变

ASTM D575

Mpa

5

compressive strength

5%应变

ASTM D575

Mpa

1

compressive strength

50%应变

ASTM D575

Mpa

1

Compression deformation

23℃ 22hr

ISO 815

%

1

Compression deformation

23℃ 22hr在110℃下后固化16小时

ASTM D395

%

1

Compression deformation

70℃ 22hr

ASTM D395

%

6

Compression deformation

70℃ 22hr在110℃下后固化16小时

ASTM D395

%

3

Thermal performance

Test Condition

Test Method

Unit

TPU/COVESTRO USA/285A

Brittle temperature

ASTM D746

°C

-

Brittle temperature

ISO 974

°C

-

vicat softening point

50℃/hr

ISO 306

°C

9

vicat softening point

50℃/hr

ASTM D1525

cm/cm/℃

9

Contact Us

Get App

Top