Material Comparison

Product Info

Product Name

Brand Name

Usages

Properties

Certificates

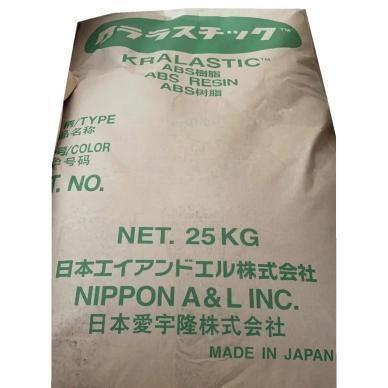

ABS GA-110G30 NIPPON A&L

KRALASTIC®

--

Filler/fiberglass reinfor,30% weight filler

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

| Basic Performance | Test Condition | Test Method | NIPPON A&L/GA-110G30 |

|---|---|---|---|

| melt mass-flow rate | 220℃/10.0kg | ASTM D-1238 | 8.0 g/10min |

| thermal performance | Test Condition | Test Method | NIPPON A&L/GA-110G30 |

|---|---|---|---|

| Hot deformation temperature | 1.80MPa,Unannealed,6.40mm | ASTM D-648 | 100 °C |

| Linear coefficient of thermal expansion | Flow | ASTM D-696 | 0.000041 cm/cm/℃ |

| UL flame retardant rating | UL 94 | HB | |

| Vicat softening temperature | ASTM D-1525 | 120 °C |

| mechanical properties | Test Condition | Test Method | NIPPON A&L/GA-110G30 |

|---|---|---|---|

| Bending modulus | 23℃ | ASTM D-790 | 7350 Mpa |

| bending strength | 23℃ | ASTM D-790 | 142 Mpa |

| Elongation at Break | 23℃ | ASTM D-638 | 3.0 % |

| Impact strength of cantilever beam gap | -30℃,6.40mm | ASTM D-256 | 39.0 J/m |

| 23℃,6.40mm | ASTM D-256 | 69.0 J/m | |

| Rockwell hardness | ASTM D-785 | 116 R scale | |

| tensile strength | Yield,23℃ | ASTM D-638 | 127 Mpa |

| Physical properties | Test Condition | Test Method | NIPPON A&L/GA-110G30 |

|---|---|---|---|

| Shrinkage rate | Flow | ASTM D-955 | 0.20-0.30 % |