Material Comparison

Product Info

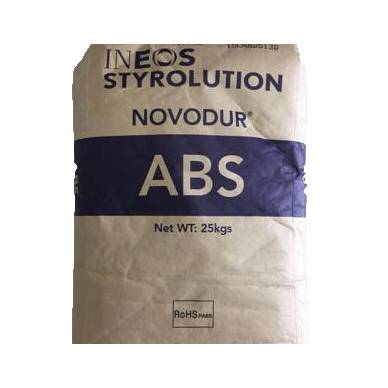

Product Name

Brand Name

Usages

Properties

Certificates

ABS GP-35 BASF GERMANY

Terluran®

Electronic and electrical enclosure,Home appliance applications,Thin walled products,Electrical tools,A wide range of applications,Especially suitable for telecommunications product

High gloss,High mobility,High temperature resistan,Impact resistance,Easy to color,Injection grade,Universal,High liquidity,High impact resistance an

UL

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

| Basic Performance | Test Condition | Test Method | BASF GERMANY/GP-35 |

|---|---|---|---|

| Combustibility | 1/16" | UL 94 | HB |

| melt mass-flow rate | 220℃×5KG | ASTM D-1238 | 3.2 g/10min |

| 220℃×10KG | ISO 1133 | 35 g/10min |

| thermal performance | Test Condition | Test Method | BASF GERMANY/GP-35 |

|---|---|---|---|

| Hot deformation temperature | 18.6kg/cm2Unannealed℃ | ASTM D-648 | 97 |

| 18.6kg/cm2Annealed℃ | ASTM D-648 | 97 | |

| Vicat softening temperature | ASTM D-1525 | 97 °C |

| mechanical properties | Test Condition | Test Method | BASF GERMANY/GP-35 |

|---|---|---|---|

| Bending modulus | ASTM D-790 | 25000 kg/cm2 | |

| bending strength | ASTM D-790 | 680 kg/cm2 | |

| Impact strength of cantilever beam gap | 1/8" | ASTM D-256 | 220J/m2 |

| 1/4" | ASTM D-256 | 220J/m2 | |

| Rockwell hardness | ASTM D-785 | 102 R | |

| tensile strength | Yield | ASTM D-638 | 680 kJ/m² |

| Physical properties | Test Condition | Test Method | BASF GERMANY/GP-35 |

|---|---|---|---|

| Shrinkage rate | ASTM D-955 | 0.3-0.6 % |