Material Comparison

Product Info

Product Name

Brand Name

Usages

Properties

Certificates

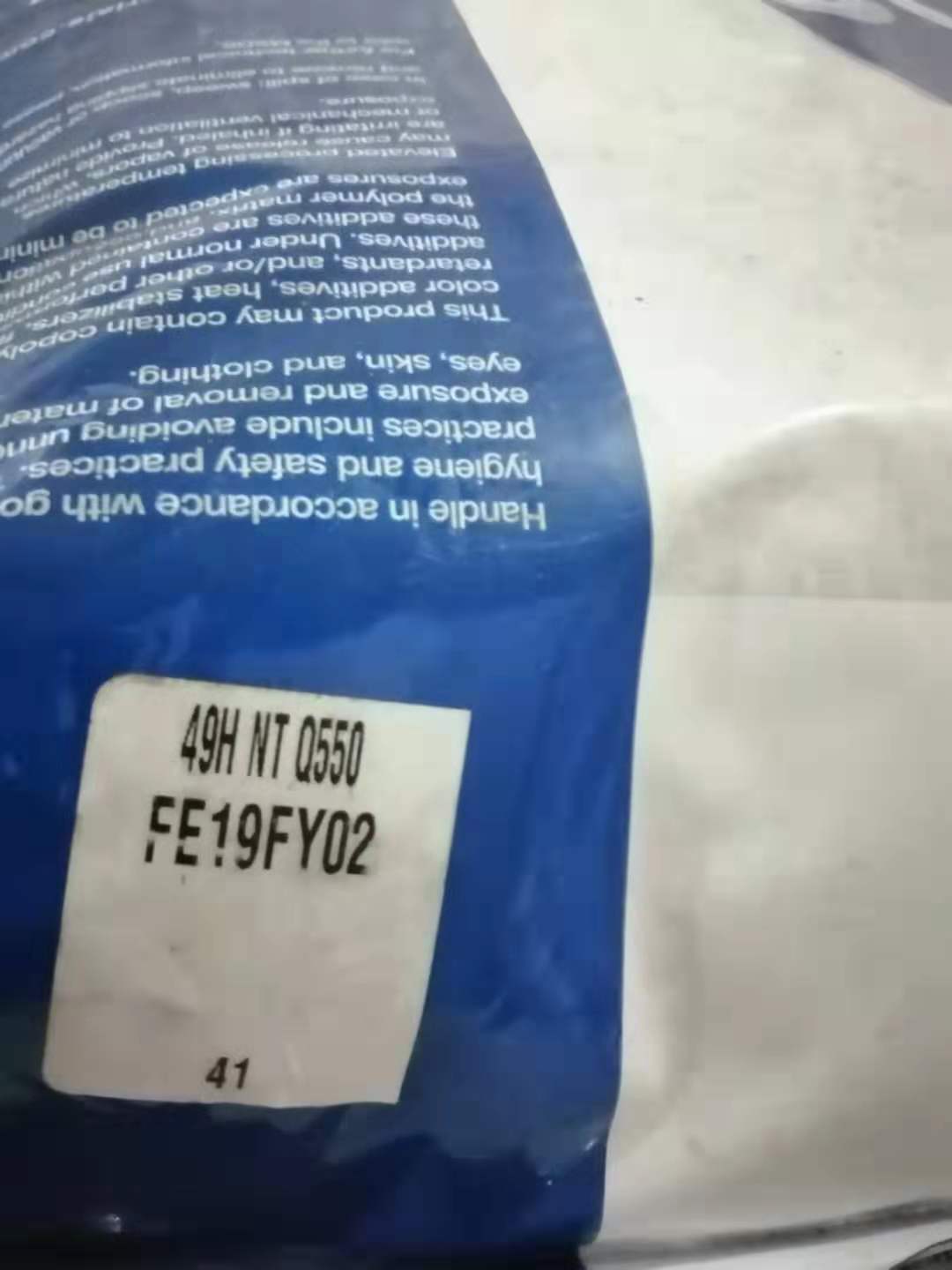

PA66 49H NT Q550 ASCEND USA

Vydyne®

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

| thermal performance | Test Condition | Test Method | ASCEND USA/49H NT Q550 |

|---|---|---|---|

| Hot deformation temperature | 0.45 MPa, Unannealed | ISO 75-2/B | 202 °C |

| 1.8 MPa, Unannealed | ISO 75-2/A | 69.0 °C | |

| Linear coefficient of thermal expansion | Across Flow : 23 to 55°C, 2.00 mm | ISO 11359-2 | 1.2E-4 cm/cm/°C |

| Flow : 23 to 55°C, 2.00 mm | ISO 11359-2 | 8.6E-5 cm/cm/°C | |

| Melting temperature | ISO 11357-3 | 260 °C | |

| RTI | 0.75 mm | UL 746 | 110 °C |

| 3.0 mm | UL 746 | 110 °C | |

| 1.5 mm | UL 746 | 110 °C | |

| RTI Elec | 0.75 mm | UL 746 | 130 °C |

| 1.5 mm | UL 746 | 130 °C | |

| 3.0 mm | UL 746 | 130 °C | |

| RTI Imp | 3.0 mm | UL 746 | 75.0 °C |

| 1.5 mm | UL 746 | 75.0 °C | |

| 0.75 mm | UL 746 | 75.0 °C |

| mechanical properties | Test Condition | Test Method | ASCEND USA/49H NT Q550 |

|---|---|---|---|

| Bending modulus | ISO 178 | 2600 Mpa | |

| bending strength | ISO 178 | 81.0 Mpa | |

| Tensile modulus | ISO 527-2 | 3040 Mpa | |

| Tensile strain | Break | ISO 527-2 | 17 % |

| tensile strength | Yield | ISO 527-2 | 70.0 Mpa |

| Break | ISO 527-2 | 46.0 Mpa |

| Electrical performance | Test Condition | Test Method | ASCEND USA/49H NT Q550 |

|---|---|---|---|

| Arc resistance | 3.00 mm | ASTM D495 | PLC 6 |

| Compared to the anti leakage trace index | 3.00 mm | IEC 60112 | PLC 1 |

| Dielectric strength | 1.00 mm | ASTM D149 | 14 KV/mm |

| High arc combustion index | 1.5 mm | UL 746 | PLC 0 |

| 3.0 mm | UL 746 | PLC 0 | |

| 0.75 mm | UL 746 | PLC 0 | |

| High voltage arc tracing rate | UL 746 | PLC 2 | |

| Hot wire ignition | 0.75 mm | UL 746 | PLC 4 |

| 1.5 mm | UL 746 | PLC 4 | |

| 3.0 mm | UL 746 | PLC 3 | |

| Volume resistivity | 0.750 mm | IEC 60093 | 1.0E+11 ohms·cm |

| Physical properties | Test Condition | Test Method | ASCEND USA/49H NT Q550 |

|---|---|---|---|

| Shrinkage rate | 横向Flow : 2.00 mm | ISO 294-4 | 1.6 % |

| Flow : 2.00 mm | ISO 294-4 | 1.8 % | |

| Water absorption rate | 24 hr, 23°C | ISO 62 | 1.3 % |

| Equilibrium, 23°C, 50% RH | ISO 62 | 2.3 % |

| impact performance | Test Condition | Test Method | ASCEND USA/49H NT Q550 |

|---|---|---|---|

| Impact strength of simply supported beam without notch | -30°C | ISO 179 | 无断裂 |

| 23°C | ISO 179 | 无断裂 |

| flammability | Test Condition | Test Method | ASCEND USA/49H NT Q550 |

|---|---|---|---|

| Automotive Materials - (thickness d = 1 mm) | FMVSS 302 | + | |

| Burning wire flammability index | 0.75 mm | IEC 60695-2-12 | 725 °C |

| 3.0 mm | IEC 60695-2-12 | 700 °C | |

| 1.5 mm | IEC 60695-2-12 | 750 °C | |

| Hot filament ignition temperature | 1.5 mm | IEC 60695-2-13 | 775 °C |

| 3.0 mm | IEC 60695-2-13 | 725 °C | |

| 0.75 mm | IEC 60695-2-13 | 750 °C | |

| UL flame retardant rating | 3.0 mm | UL 94 | HB |

| 0.75 mm | UL 94 | HB | |

| 1.5 mm | UL 94 | HB |

| injection | Test Condition | Test Method | ASCEND USA/49H NT Q550 |

|---|---|---|---|

| drying temperature | 80 °C | ||

| drying time | 4.0 hr | ||

| Mold temperature | 65 to 95 °C | ||

| Processing (melt) temperature | 285 to 305 °C | ||

| Spray nozzle temperature | 280 to 310 °C | ||

| Suggested maximum material return ratio | 25 % | ||

| Temperature at the front of the material cylinder | 280 to 310 °C | ||

| Temperature at the rear of the barrel | 280 to 310 °C | ||

| Temperature in the middle of the barrel | 280 to 310 °C |