Material Comparison

Product Info

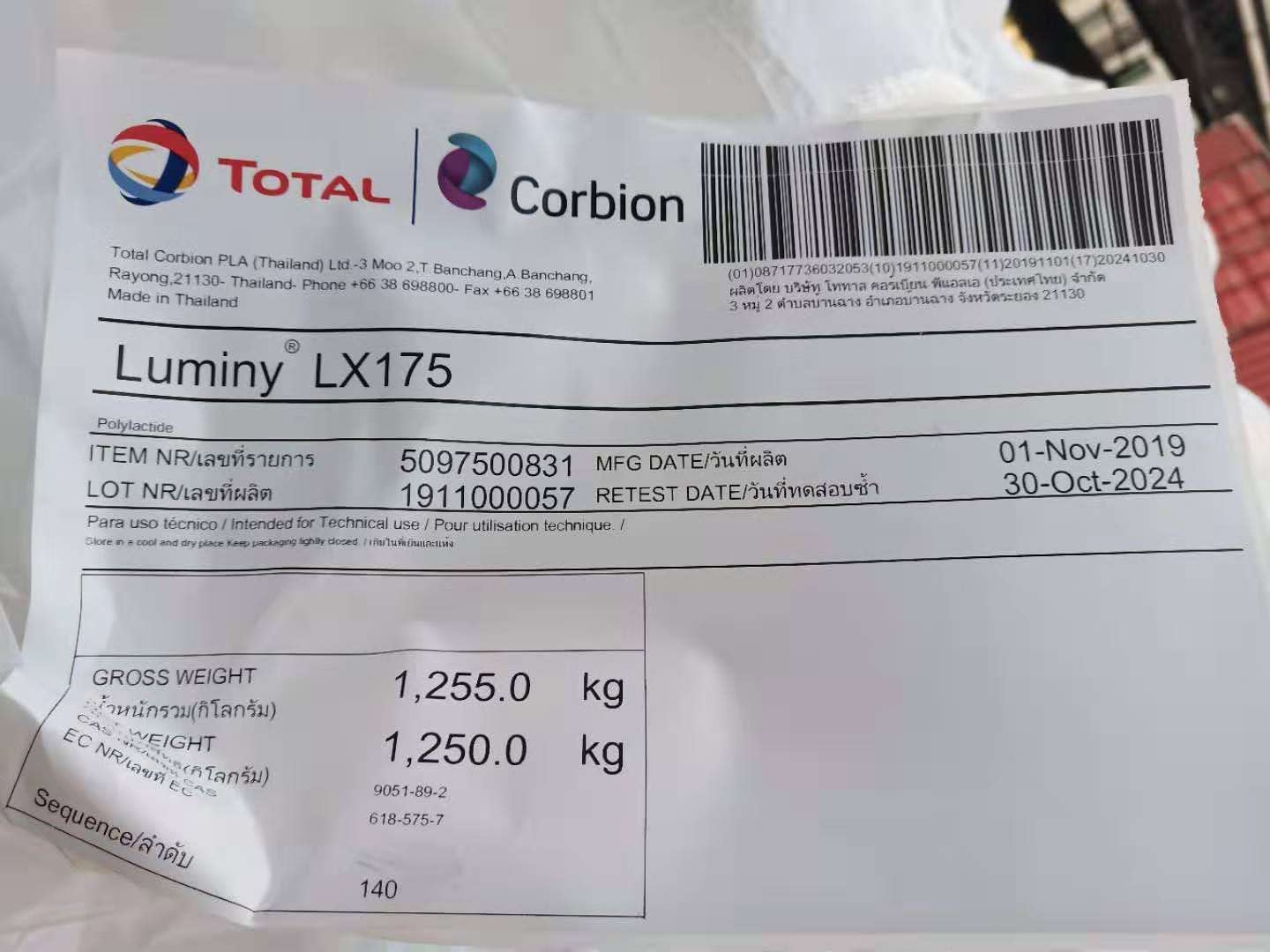

Product Name

Brand Name

Usages

Properties

Certificates

PLA LX175 TOTAL THAILAND

Luminy®

film,fibre

high viscosity,Food contact compliance,Low flow

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

| thermal performance | Test Condition | Test Method | TOTAL THAILAND/LX175 |

|---|---|---|---|

| Glass transition temperature | DSC | 55.0 to 60.0 °C | |

| Melting temperature | DSC | 155 °C | |

| Monomer Residue | Internal Method | < 0.30 % |

| mechanical properties | Test Condition | Test Method | TOTAL THAILAND/LX175 |

|---|---|---|---|

| Tensile modulus | ISO 527-2 | 3500 Mpa | |

| Tensile strain | Break | ISO 527-2 | < 5.0 % |

| tensile strength | ISO 527-2 | 45.0 Mpa |

| Physical properties | Test Condition | Test Method | TOTAL THAILAND/LX175 |

|---|---|---|---|

| melt mass-flow rate | 210°C/2.16 kg | ISO 1133 | 8.0 g/10 min |

| 190°C/2.16 kg | ISO 1133 | 3.0 g/10 min | |

| water content | Karl Fisher | < 400 ppm |

| squeeze out | Test Condition | Test Method | TOTAL THAILAND/LX175 |

|---|---|---|---|

| drying temperature | 85 °C | ||

| drying time | 4.0 to 6.0 hr | ||

| Material barrel temperature | 20 to 40 °C | ||

| Oral mold temperature | 190 to 210 °C | ||

| Suggested maximum moisture content | 0.025 % | ||

| Temperature in Zone 1 of the material cylinder | 170 to 190 °C | ||

| Temperature in Zone 2 of the material cylinder | 190 to 210 °C |