Material Comparison

Product Info

Product Name

Brand Name

Usages

Properties

Certificates

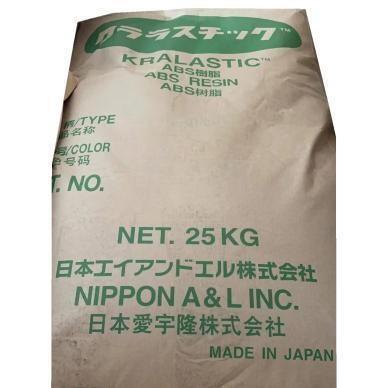

ABS UT-61 NIPPON A&L

KRALASTIC®

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

| Basic performance | Test Condition | Test Method | NIPPON A&L/UT-61 |

|---|---|---|---|

| melt mass-flow rate | 220℃/10kg | ASTM D-1238 | 33 g/10min |

| density | 23℃ | ASTM D-792 | 1.05 g/cm |

| Mechanical properties | Test Condition | Test Method | NIPPON A&L/UT-61 |

|---|---|---|---|

| Flexural modulus | 23℃ | ASTM D-790 | 2210 Mpa |

| elongation at break | 23℃ | ASTM D-638 | 26 % |

| bending strength | 23℃ | ASTM D-790 | 68 Mpa |

| tensile strength | 23℃ | ASTM D-638 | 48 Mpa |

| IZOD notch impact strength | 23℃ 6.4mmt | ASTM D-256 | 137 J/m |

| -30℃,6.4mmt | ASTM D-256 | 59 J/m | |

| Rockwell hardness | 23℃ | ASTM D-785 | 116 R-Scale |

| processability | Test Condition | Test Method | NIPPON A&L/UT-61 |

|---|---|---|---|

| mold temperature | 200-260 °C |

| physical property | Test Condition | Test Method | NIPPON A&L/UT-61 |

|---|---|---|---|

| Mold shrinkage rate | ASTM D-955 | 0.4-0.8 % |

| Thermal performance | Test Condition | Test Method | NIPPON A&L/UT-61 |

|---|---|---|---|

| UL flame retardant rating | UL94 | HB calss | |

| 1.82Mpa | ASTM D-648 | 89 °C | |

| Ball indentation temperature | 95 °C | ||

| vicat | 1.0kgf | ASTM D-1525 | 106 °C |

Contact Us

Get App

Top