Material Comparison

Product Info

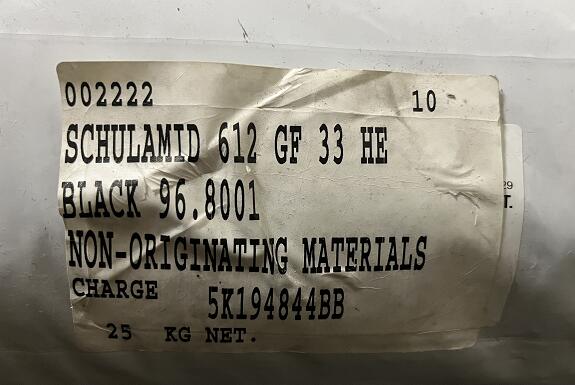

Product Name

Brand Name

Usages

Properties

Certificates

PA612 612GF33 HE A SCHULMAN USA

SCHULAMID®

--

Glass fiber reinforced

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

Plastic Datasheets

| Thermal Properties | Test Condition | Test Method | A SCHULMAN USA/612GF33 HE |

|---|---|---|---|

| Heat Deflection Temperature | 0.45 MPa, 未退火 | ISO 75-2/Bf | 215 °C |

| 1.8 MPa, 未退火 | ISO 75-2/Af | 195 °C |

| Injection | Test Condition | Test Method | A SCHULMAN USA/612GF33 HE |

|---|---|---|---|

| Suggested Max Regrind | 20 % | ||

| Suggested Max Moisture | 0.040 到 0.10 % | ||

| Processing (Melt) Temp | 240 到 280 °C | ||

| Drying Time | 3.0 到 6.0 hr | ||

| Drying Temperature | 80 °C | ||

| Mold Temperature | 50 到 90 °C |

| Physical | Test Condition | Test Method | A SCHULMAN USA/612GF33 HE |

|---|---|---|---|

| Viscosity number | H2SO4(硫酸) | ISO 307 | 125 cm³/g |

| Mechanical Properties | Test Condition | Test Method | A SCHULMAN USA/612GF33 HE |

|---|---|---|---|

| Tensile Modulus | ISO 527-2/1A/1 | 10500 Mpa | |

| Tensile Strain | 断裂 | ISO 527-2/1A/5 | 3.2 % |

| Flexural Stress | 3.7% 应变 | ISO 178 | 280 Mpa |

| 3.5% 应变 | ISO 178 | 280 Mpa | |

| Tensile Stress | 断裂 | ISO 527-2/1A/5 | 175 Mpa |

| Flexural Modulus | ISO 178 | 10000 Mpa |

| Impact Properties | Test Condition | Test Method | A SCHULMAN USA/612GF33 HE |

|---|---|---|---|

| Charpy Unnotched Impact Strength | -30°C | ISO 179/1eU | 65 kJ/m² |

| 23°C | ISO 179/1eU | 80 kJ/m² |

Contact Us

Get App

Top