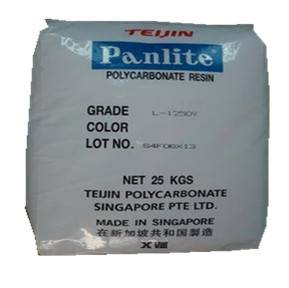

PC PANLITE® L-1250Y JIAXING TEIJIN

46

- Unit Price:

- $2280 USD/MT

- Packaging Specification:

- 25KG/PKG

- Supply Quantity:

- 22MT

- Delivery Terms:

- FOB

- Port of Loading:

- China Main Port

- Accepted Payment Methods:

- T/T

- Shipping:

- Negotiate supplier for shipping details

Supplier Information

Shenzhen City Yu Bang Plastic Materials Co., Ltd.

+86 153****68

luoy********

For more detailed information including pricing, customization, and shipping, please contact supplier.

Technical Data Sheet

There is currently no data available

Other Prices

| Port of Loading | Unit Price |

|---|---|

| China Main Port | 2138 USD/MT |

| China Main Port | 2400 USD/MT |