ABS is a terpolymer composed of acrylonitrile (A), butadiene (B) and styrene (S). Among them, acrylonitrile endows the material with hardness, heat resistance and chemical resistance. Butadiene improves the impact resistance and toughness of the material. Styrene improves the processing fluidity and surface gloss. ABS is a high - performance engineering plastic widely used in the fields of electronics and electrical appliances, household appliances, daily necessities. Its excellent mechanical properties, thermal stability and processing properties make it an indispensable material in many industries.

1.Advantages and Disadvantages of ABS

1.1 Advantages

Electrical Insulation, Impact Resistance, Strength and Stiffness, Versatility, Chemical Resistance, Surface Finish

1.2 Disadvantages

Poor Weather Resistance, Flammability, Dimensional Instability

2.Main Categories of ABS

2.1 Classification by Use

General-Purpose Type, Flame-Retardant Grade, Heat Resistance Grade, Electroplating Grade, Transparent Grade

2.2 Classified by Modification Type

Heat-Resistant Modified ABS, Flame-Retardant Modified ABS, Antistatic Modified ABS, Glass Fiber Reinforced ABS

3.Application Areas of ABS

ABS is widely used in various industries due to its balanced performance and ease of processing.

Automotive Industry, Electronics and Electrical Appliance Industry, Building Materials Industry, Packaging industry, furniture industry , sports and entertainment products , mechanical and instrument industry

4.Typical Grade

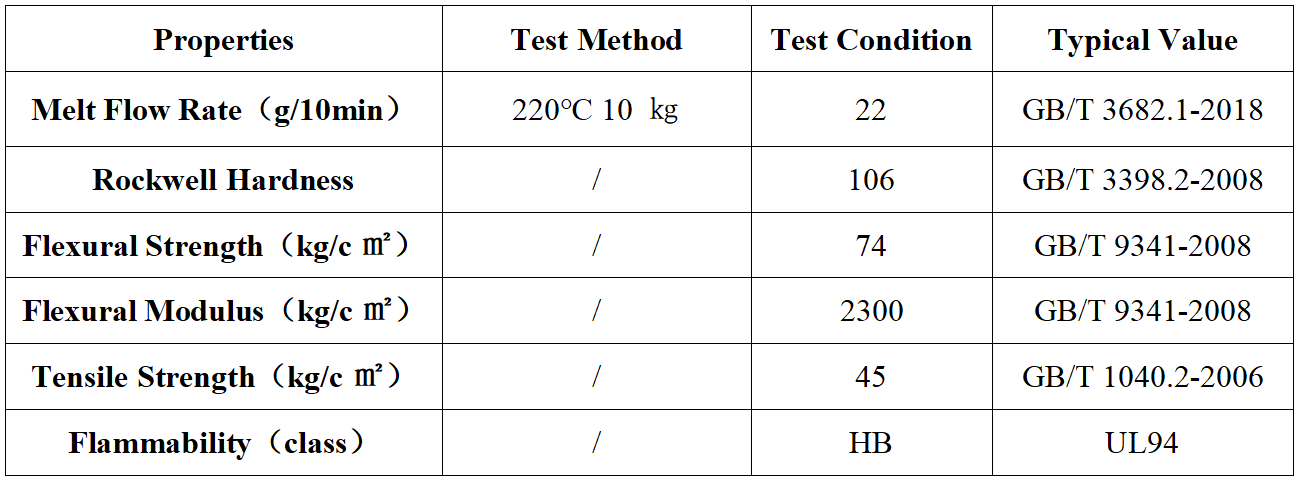

4.1 ABS HI-121H

Characteristic: Excellent mechanical properties

Application: Electrical electronic products, Other goods

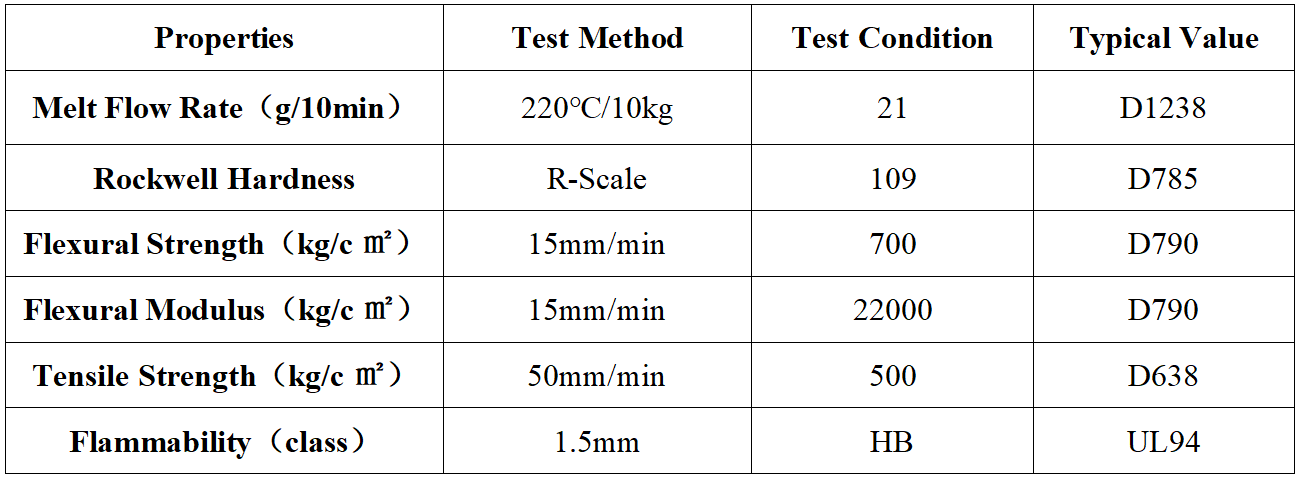

4.2 ABS ZA0211

Characteristic: High gloss, High impact

Application: Home appliances, Electronic electrical products

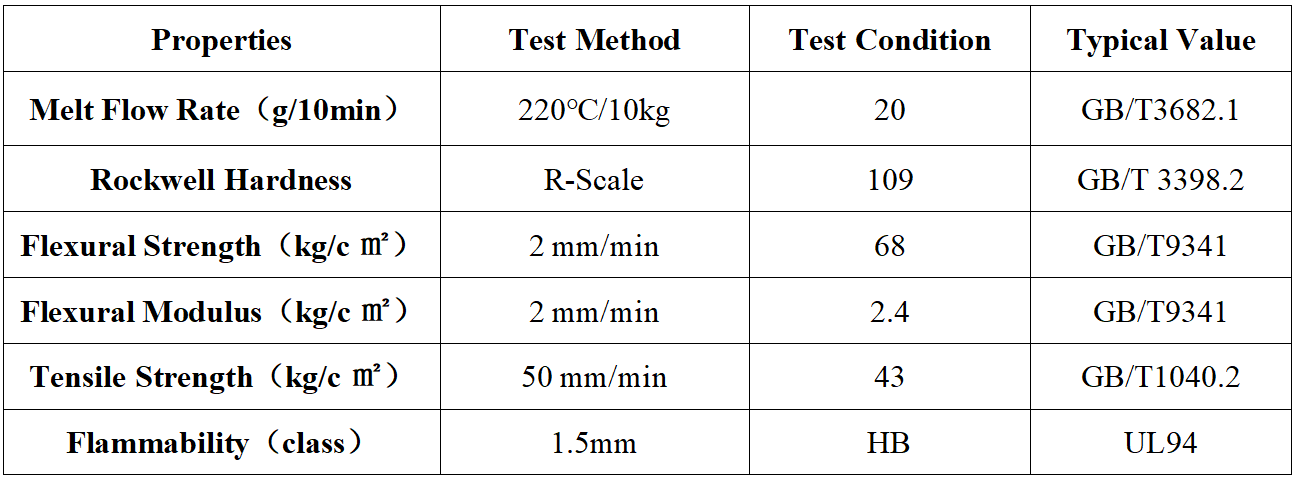

4.3 ABS 0215A

Characteristic: High gloss, High rigidity, Good balance of rigidity and toughness, Excellent wear resistance performance

Application: Small household appliances, Electronic appliances, Daily necessities, Toys